NAGASEP

Silicone Rubber Hollow Fiber Membrane Module “NAGASEP”

for advanced operations of gas, vapor and solution

NAGASEP is…

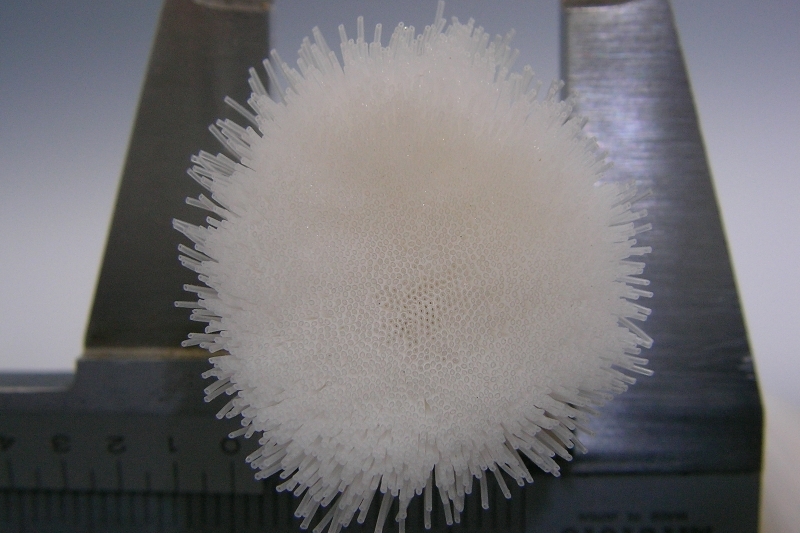

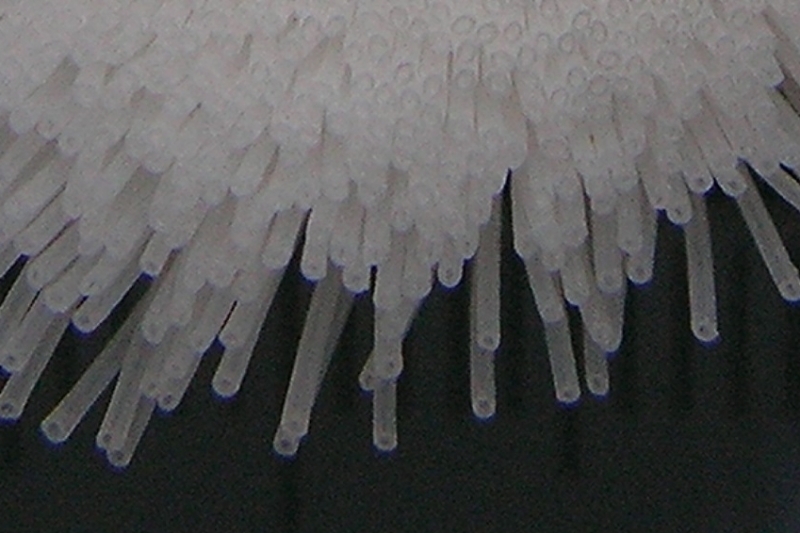

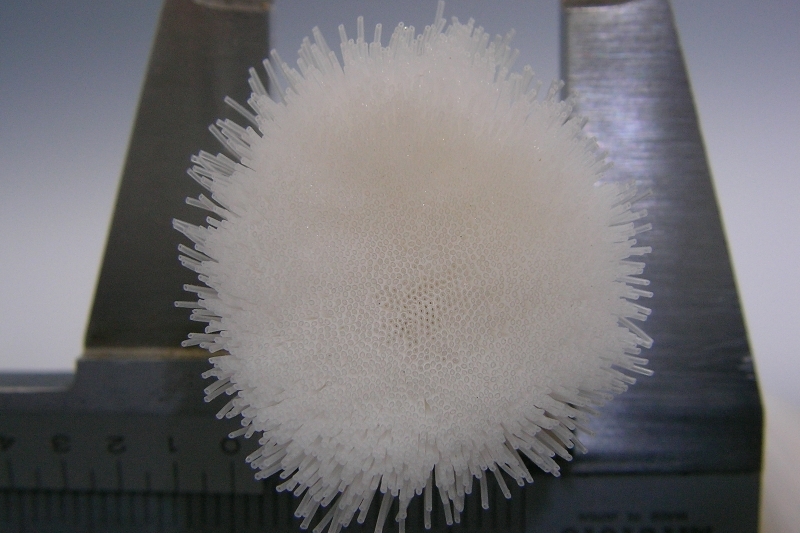

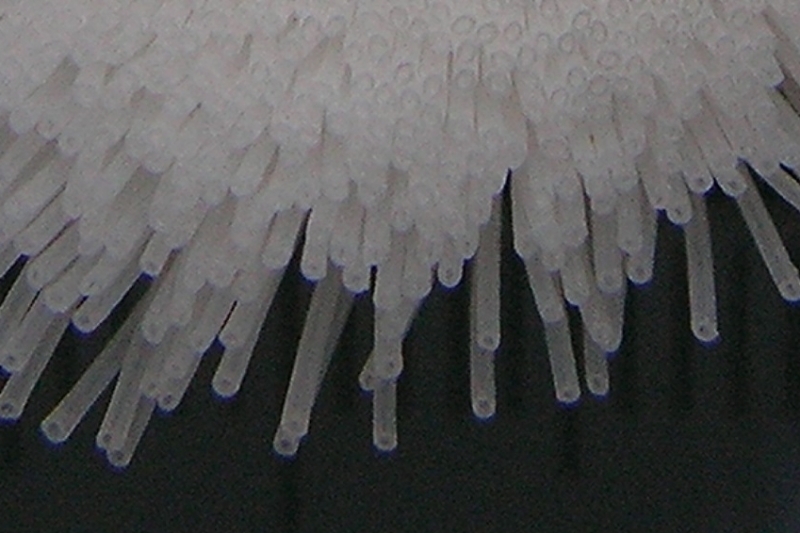

NAGASEP is a functional gas separation module which made aggregate of ultrafine Silicone-membrane Hollow-fiber.

NAGAYANAGI’s Silicone-membrane Hollow-fiber is high dimensional accuracy by own technology.

NAGASEP can be applied in many fields such as gas separation, liquid supply or liquid degassing.

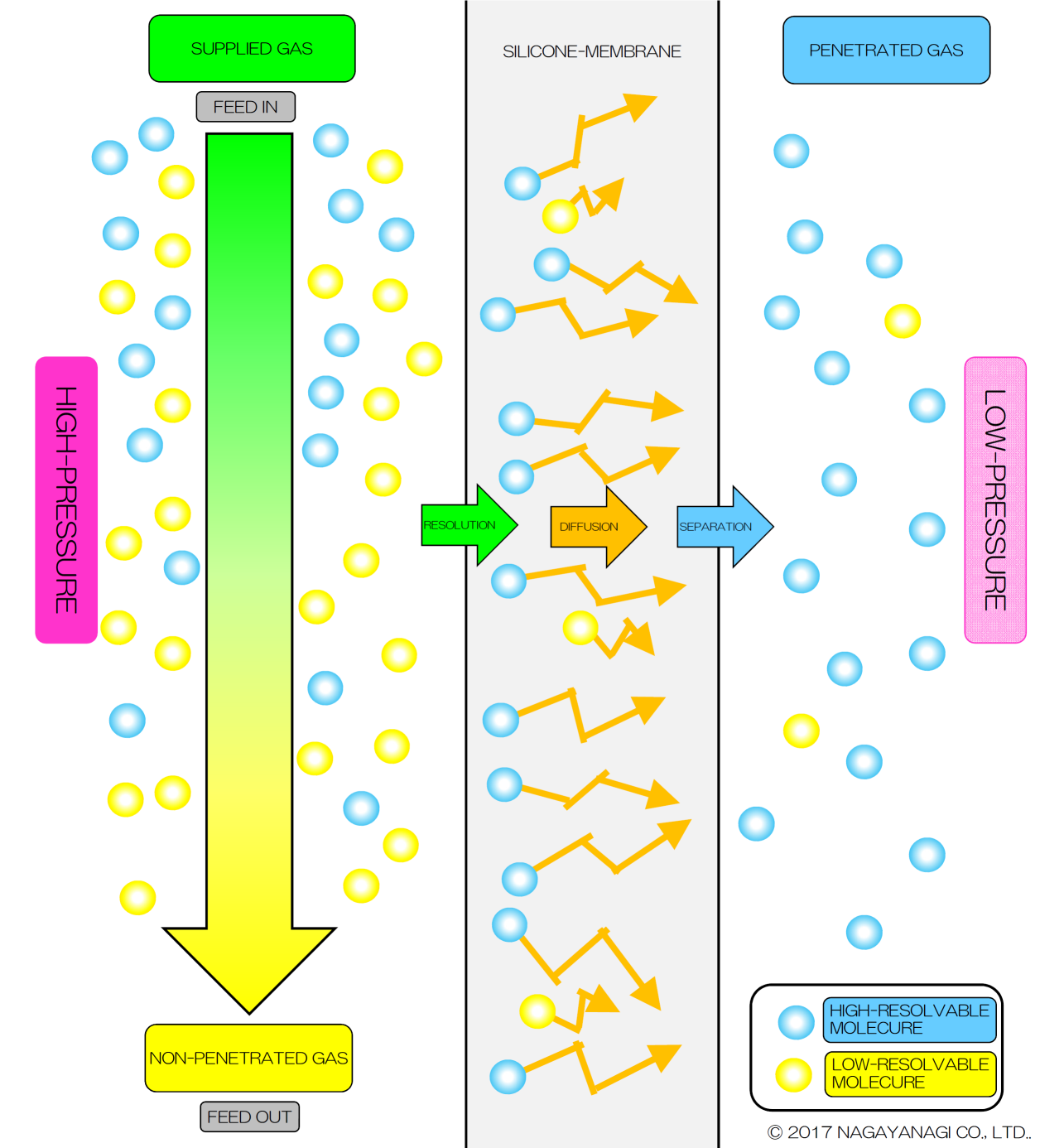

NAGASEP utilize the selective permeability of silicone.

Silicone is the best to permeate gases among polymers.

Silicone has features such as heat resistance, chemical resistance, inert, etc.

Information on NAGASEP

- solvent resistance

-

- NAGASEP is hydrophobic and excellent in selective permeability of organic matter.

- NAGASEP is resistant to organic solvents.

- NAGASEP can separate and recover VOC(volatile organic compounds) from wastewater and mixed gas.

- heat-resistance

-

- NAGAYANAGI’s Silicone-membrane Hollow-fiber is heat-resistance up to 200°C

- NAGASEP can be autoclave sterilize.

- Long life application

-

- Silicone is unaffected by UV(ultraviolet)-rays and ozone.

- NAGAYANAGI’s Silicone-membrane Hollow-fiber don’t clog, because it is non-porus.

- Compactness

-

- Minimum size of our Silicone-membrane Hollow-fiber thickness is 0.02mm.

- It is the thinnest among Silicone-membrane Hollow-fiber.

- You can reduce the size/volume of the equipment.

- Customerization and special tuning

-

- NAGAYANAGI’s Silicone-membrane Hollow-fiber is excellent in flexibility. => You can weave like cloth.

- NAGAYANAGI can design according to the application.

Example of Applications

One side of the membrane; Pour gas or mixtures of liquid.

The other side; Pressurize with gas or decompress with a vacuum pump.

- Environment

-

- Recovery of VOC(volatile organic compounds) in the atmosphere.

- Recovery of alcohol from alternative fuel by pervaporation.

- Recovery of organic solvent in liquid by pervaporation.

- Separate and recovery of specific gas generated in the manufacturing process.

- Medical

-

- Artificial lung.

- Gas exchanger for animal cell culture (O2 supply, CO2 emission).

- Deaerator of blood analysis equipment (Defoaming of test solution / cleaning solution).

- Manufacture of Pharmaceutical-microsphere.

- Food / Drink, Water purification

-

- Supplying oxygen to the Fermentation-liquor or brewing vinegar and liquor Culture of Chlorella.

- Concentrate atmospheric CO2 (For House cultivation, plant factory).

- Aerobic microbial treatment (Wastewater treatment).

- Analytical instruments

-

- Supplying oxygen to the Fermentation-liquor or brewing vinegar and liquor Culture of Chlorella.

- Concentrate atmospheric CO2 (For House cultivation, plant factory).

- Aerobic microbial treatment (Wastewater treatment).

* NAGAYANAGI design NAGASEP according to customer’s request.

The Specification of NAGASEP

1. Hollow-Fiber

| Type | M30 | M40 | M60 | M80 |

|---|---|---|---|---|

| Pressure Resistance: MPa | 0.1 | 0.2 | 0.3 | 0.4 |

| Active Temperature: °C | -60~+200 | |||

| Tensile Strength: kg/cm2 | 91 | |||

| Maximum Elongation: % | 370 | |||

| O2 Permeations Rate: cc/m2・min・atm | 700 | 500 | 380 | 260 |

2. Permeability

| N2 | 2.5 | H2 | 5.7 | Xe | 22.8 |

|---|---|---|---|---|---|

| CO | 3.0 | CH4 | 8.3 | C3H8 | 25.0 |

| Ne | 3.1 | Kr | 10.0 | H2S | 88.4 |

| He | 3.2 | C2H4 | 13.3 | NO2 | 133.0 |

| O2 | 5.0 | CO2 | 18.5 | H2O (steam) |

318.0 |

| NO | 5.3 | C2H6 | 16.0 | ||

| Ar | 5.3 | NH3 | 20.9 | CS2 | 793.0 |

* This data is a reference value for gas permeability comparison. It does not guarantee performance.

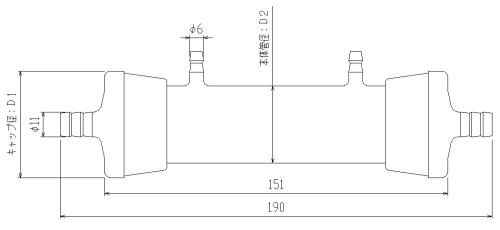

3-1. Module for Trial

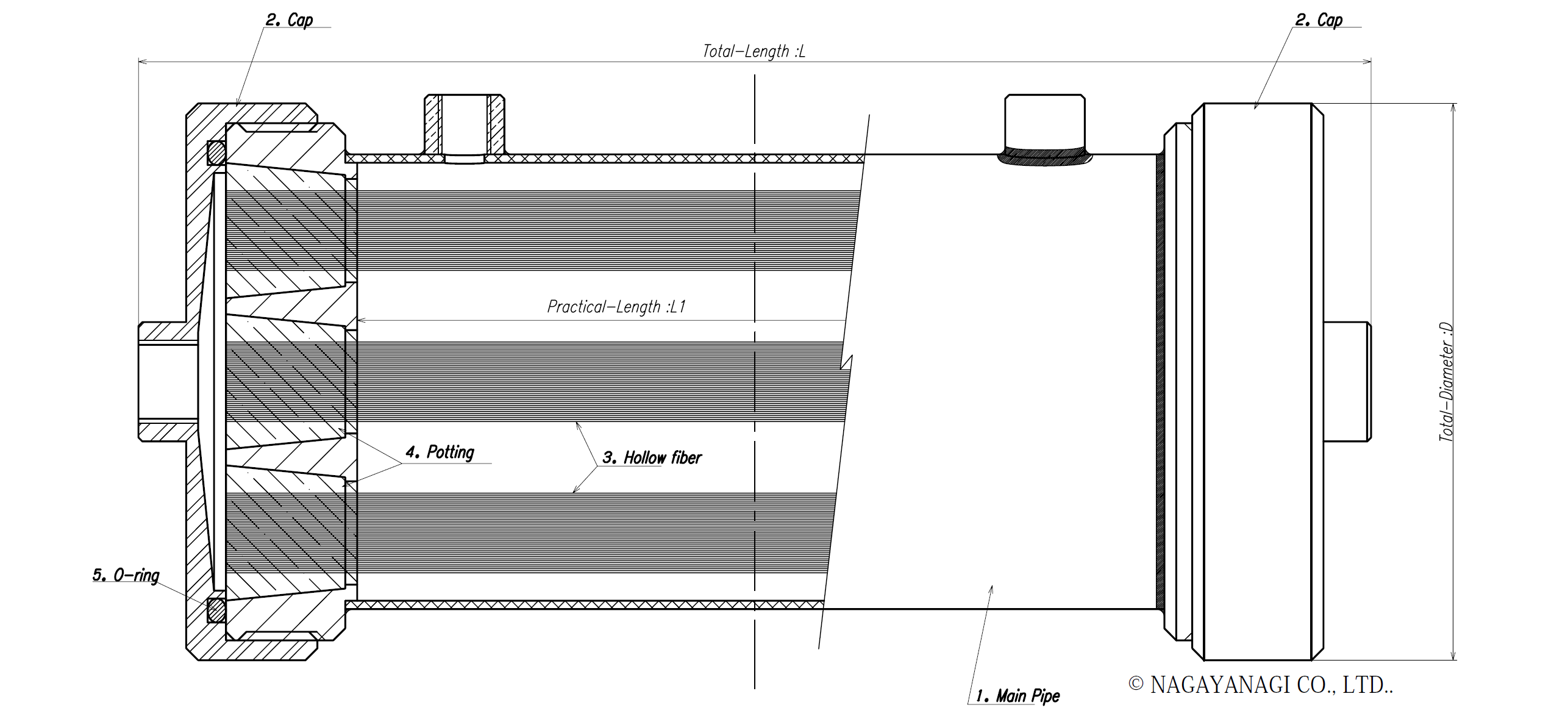

3-2. Schematic Drawing

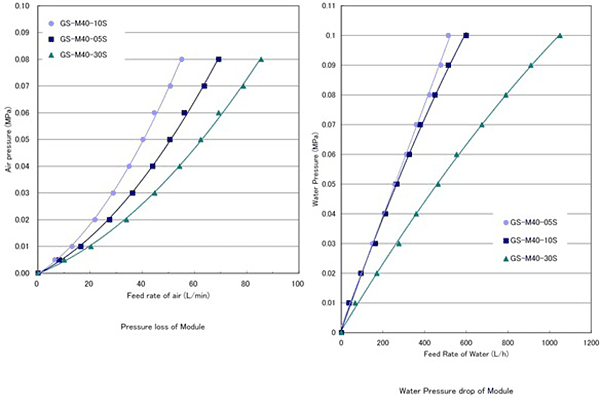

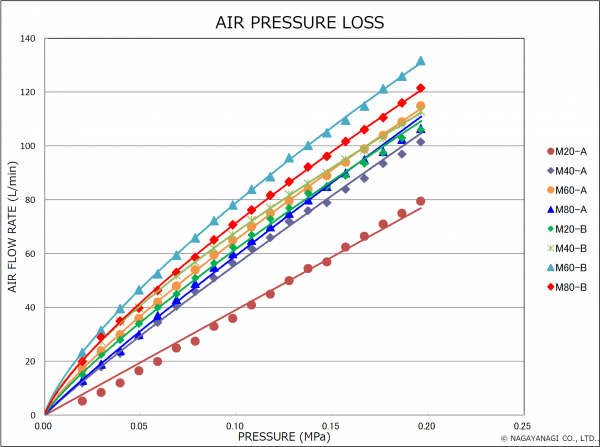

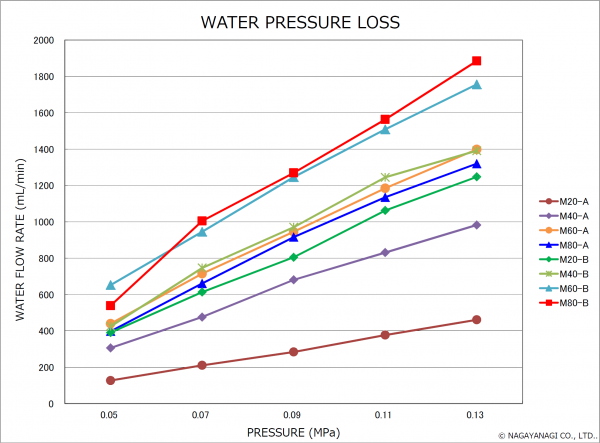

3-3. Pressure-loss Data

4-1. Standard-Module for Actual-Mechanism

| Model | GS-M40-05S | GS-M40-10S | GS-M40-30S |

|---|---|---|---|

| Material of Hollow-Fiber | Silicone | ||

| Material of Housing | Aluminum or PVC | ||

| Material of Potting | Silicone | ||

| Type of Hollow-Fiber | M40 | M40 | M40 |

| Number of Hollow-Fiber | 38,500 | 49,000 | 104,500 |

| Practical-Length: L1/mm | 200 | 320 | 440 |

| Practical-Area of Membrane: m2 | 4 | 10 | 30 |

| Module Size: DxL/mm | 140×310 | 160×436 | 230×594 |

| Screw-size for Connection-Port | PT-1/4 at Main-Pipe PT-1/2 at Cap |

PT-3/8 at Main-Pipe PT-1 at Cap |

PT-1/2 at Main-Pipe PT-11/2 at Cap |

| Pressure Resistance(Mpa) | 0.2 | ||

| Heat Resistance(°C) | 200(Al) / 80(PVC) | ||

* NAGAYANAGI design NAGASEP according to customer’s request.

4-2. Schematic Drawing

4-3. Pressure-loss Data